Yesterday I offered a quiz to my loyal readers. Which readers could figure out what these four things had in common? Today I announce the winners and I offer some discussion and explanation as to how these four things are really very nearly exactly the same.

The winners, in sequence of when they slapped the buzzer, were:

My characterization of the common element is an engineer acknowledging that a bad thing might happen, and trying to control the way it might happen so as to minimize the harm flowing from the bad thing. This express acknowledgment of the possibility of failure, and this direct effort to plan for its occurrence, stands as an example of the highest and best use of the engineer’s skills. If you run into an engineer at a cocktail party and this sort of thing comes up in the discussion, I urge you to go over to the engineer and shake his or her hand and say “thank you”.

That’s my characterization, but I invite you to read the very thoughtful comments of those five readers each of whom had his own nice way of using words to convey the common element.

The first photograph shows a spillway. The point of the spillway is to provide a controlled path for water if the water level gets too high behind a dam. There is nearly always some other mechanism (typically a gate valve) designed into the dam for controlling the water level, but that other mechanism could fail, for example jamming in a closed position. Or maybe a human user might close the gate valve and forget to reopen it. Instead of overflowing the dam and perhaps destroying the dam, the water flows in a harmless way over the spillway. Yes, the spillway added to the cost of the dam (above and beyond the cost of the gate valve) but the cost is worthwhile and we have some civil engineer to thank for this smart thinking.

The next photograph is of course a fuse. A wire can get too hot if an amount of current is allowed to flow through the wire that exceeds the capacity of the wire. Pretty likely if the wire were to get too hot, it would melt or vaporize and this would break the connection, and the current flow would cease. But that way of dealing with an overcurrent event is uncontrolled. It might start a fire. The idea of the fuse is to plan in advance, choosing where exactly the melting will happen. The melting, if it happens, is at a place that is protected from fire and involves a material that is selected so that it will not get too hot when it melts. We have an electrical engineer to thank for this smart thinking.

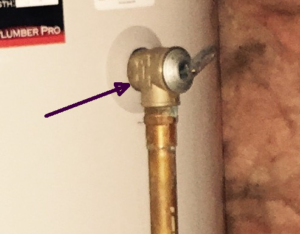

Turning to the fourth photograph, many homeowners will have instantly recognized a high-pressure relief valve. The idea is that if the aquastat or burner controller on the water heater were to fail “on”, so that the heating element or flame were to cause the water tank to get too hot, there is the risk that the pressure would get too high and the tank would burst. This would of course happen in some uncontrolled way, with scalding hot water shooting off in unintended directions. Or we must consider that a human user might do something stupid in the setting of the aquastat or burner controller. The relief valve permits the plumber to plan in advance where the hot water would go if there were an overpressure situation. Oh and another nice thing about the relief valve is that it is designed so that it can reset, meaning that if the aquastat or controller gets replaced promptly, or the stupid mistake of the human user is corrected, the tank can continue in service without needing to be replaced.

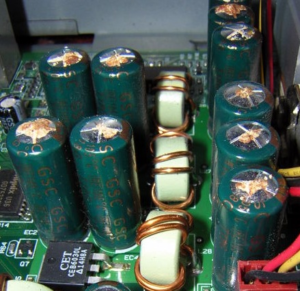

Which brings us back to the plus-shaped scoring on the aluminum top of the electrolytic capacitor. How many of our readers knew, or figured out, what this was and why it is there? How many of our loyal readers were ready to slap the buzzer because they figured out just how this is very nearly exactly the same as the things in the other three photographs? Five of them, as it turns out, or more accurately, at least five of them.

My first encounters with electrolytic capacitors happened a long time ago when I started playing around with electronics as a teenager.

The classic capacitor that we all studied during the electricity-and-magnetism chapter of our first-year physics class was assumed to be two flat plates of some particular area, separated by some spacing, giving rise to some “capacitance”. “Capacitance” is a defined term, and it is defined as the ratio of charge to voltage. You load up the capacitor with some amount of charge Q and you look to see what voltage V develops across the plates. The capacitance C is defined as Q/V.

By the way let me comment on the fact that this is one of the things that nobody ever seems to remark upon at any point during any of the four years of college or university when one is working toward a science or engineering degree. It is, I suggest, cause for some sense of wonder at how nature works, that anything would turn out to be linearly related to anything else. Why exactly is it that the universe around us behaves this way?

What puzzles me almost as much is that nobody stops to talk about this. The chemistry professor tells us that the shift in boiling point is (within limits, and for non-ionic solutes) linearly related to the molality (not molarity!) of the solute. Does the chemistry professor then stop and get teary-eyed for a moment about the astonishing thing that this turns out to be linear? No, at least not in my chemistry class. The mechanical engineering professor introduces Hooke’s law that if you pull a spring twice as hard, it extends twice as far. Linear! Followed by a moment of silent reflection in the class as to how this could be? Nope. The electrical engineering lecturer who tells us Ohm’s law — that for many conductive materials the current that you will observe flowing through the material will turn out to be linearly related to the voltage applied to the material. Linear! Followed by a comment that nature is remarkable in this way? No, not in my class. Very little happens except that everybody sort of checks that box in the lecture notes, and then everybody moves on. Days, weeks, or maybe years later, as a direct consequence of the lecturer having never taken even a moment to comment that not everything is linear, the student is flummoxed to find that with almost anything that you really care about, like an ordinary toaster or light bulb or electric motor, the relationship between the voltage applied and the current that is observed to flow is not even close to being linear.

It is the nonlinearities that make life rich. The sound from a violin string, because of the drawing of the bow with rosin on the horsehairs, is completely due to nonlinearities in the sticking friction relationship between the horsehairs and the violin strings. If a soufflé rises as the chef hopes, it is because of nonlinearities in the behavior of egg white so that bubbles are formed. It’s all surface phenomena of course.

I suppose it’s possible I have digressed ever so slightly from our topic. So anyway there you are, it is first year of physics class and you are told how to predict the capacitance of the capacitor given the physical dimensions of the capacitor plates, the spacing, and an identification of the material lying therebetween. If you know the area of the plates and the spacing, and if you know what lies between the two plates (for example a vacuum in the first exercise that is always given to the first-year physics student) then you can work out the capacitance of the capacitor. A so-called “dielectric constant” is characteristic of that material (assuming it is homogeneous and isotropic) and you do a bit of math and (because, yes, almost everything turns out to be linearly related to everything else!) you can work out C. And then you can do the actual experiment and C will turn out to fulfill the relationship Q=CV.

An electrolytic capacitor contains, oddly enough, an electrolyte which is an icky goo deposited between the plates of the capacitor. Why the icky goo?

It turns out that almost any time you construct a capacitor, with almost any material you pick for your dielectric, you end up with C being a lot smaller than you might think. Most capacitors use some fairly ordinary solid substance such as a ceramic material between the plates. The “capacitance” of a garden-variety capacitor is often strikingly small, measured in mere microfarads or even mere picofarads. If you decide that for some circuit that you are designing, you need a lot of capacitance, you might not be satisfied with picofarads or microfarads. You might want a large number of microfarads, or even millifarads. Except that you do the math and to get your desired number of millifarads you might need really big capacitor plates, maybe plates that would have to be the size of the room that you are standing in. So the people who devoted their lives to this stuff in the late 1800s and early 1900s looked at the only other thing that you can fiddle with which is your choice of the material between the plates. What they found is that if you roll up the capacitor like a roll of toilet paper, with alternating layers of metal foil, you can fit two capacitor plates into a small cylindrical housing. And you do some particular surface treatments on the metal foils. And you fill the housing with some specially selected sticky yucky goo containing eleven secret herbs and spices. And the amount of capacitance that you can cram into that small volume is much more than you would ever think, as compared with any of the other ways that people make capacitors. (Surface phenomena again.)

So why does anybody use any kind of capacitor other than electrolytic capacitors? Why for example do people still use those ceramic capacitors that have such small capacitances? It turns out that there are three major drawbacks to the use of the sticky yucky goo as your dielectric instead of a boring old ceramic. One problem is that electrolytic capacitors are extremely polarity sensitive. A second problem is that given the type of goo and the physical dimensions, you can only apply some very limited number of volts to to the capacitor. Put too many volts across the goo, or put a reverse polarity across the capacitor, and the capacitor fails. Which leads to the third problem, which is that when an electrolytic capacitor fails, it usually does so in a very dramatic fashion. The goo boils, turning to gas, expanding very fast. The danger is that the capacitor might explode. The bedroom where I grew up as a child came to have a dark stain on the ceiling because of my applying a very high level of reverse voltage to an electrolytic capacitor. (I have a vague recollection that I may have done this on purpose to see what would happen, specifically because I had read somewhere that you are not supposed to do it.) The goo shot out of the capacitor and came to rest on the ceiling. The stain was still there years later.

Once again I suppose it’s possible I have digressed ever so slightly from our topic. Which brings us back to the plus-shaped scoring. The plus-shaped scoring is a place where the cylindrical aluminum housing is made thinner, so that if the capacitor overheats, the goo will go leak out (hopefully slowly) at a controlled location. Were it not for the scoring, there is the danger the pressure would build up to a higher level before the housing gave way in some more uncontrolled fashion.

This part of the discussion reminded me about the capacitor plague, which happened between about 1999 and 2007. During these years there were large numbers of failures of electrolytic capacitors made by companies that nobody had heard of before. You can see some of them in this photograph. In each case the scored area had burst and electrolyte had oozed out, because the capacitor had overheated.

I was interested to learn recently that the prevailing view in the industry nowadays is that the large number of capacitor failures in this plague between 1999 and 2007 was due to industrial espionage gone wrong. The main trade secret for electrolytic capacitors is, of course, the recipe for the goo. It seems that some employee of a well-known maker of electrolytic capacitors had miscopied the ingredient list for the goo on his way to his new job with a newly established maker of electrolytic capacitors. And then it seems a second person copied that ingredient list on his way to a new job with yet another newly established maker of electrolytic capacitors. Millions of defective capacitors rolled off the production lines of the two new companies and found their way into computer motherboards, computer power supplies, and video cards. It usually took a couple of years for a capacitor with the faulty electrolyte to burst, so it took a few years for the makers of the motherboards, computer power supplies, and video cards to catch on that they should switch to different vendors for the electrolytic capacitors.

Thank goodness the failed capacitors from those two companies had the scoring on top.

Carl, great follow-up, thank for posting. Since it’s Friday, I have to share my hot water tank pressure relief valve story. Was coming back from a client meeting in rural upstate NY and stopped at a convenience store for snack and to use the rest room. When using a fixture of said rest room, I noticed that right at eye level on a shelf about a foot away was a small (~10gal) hot water tank for the sink hot water. Also right at eye level was the pressure relief valve with a short stub of pipe pointed straight down at… yeah. Wow. I finished up fast and got out of there. Mentioned on my way out “tell your boss the hot water tank in the men’s room is dangerous and needs to be fixed.” If it were today, I think I would have taken a picture of the whole setup, added “WHAT COULD POSSIBLY GO WRONG HERE?” and made a meme of it.

Yeah, the plumbing code always says there has to be one of those relief valves. And then the plumbing code usually says almost nothing about where the exit path actually has to go. What you will often see is a nice clean installation with a pipe running to a drain somewhere. Of course that pipe costs a few pennies, and it takes some amount of effort on the part of the plumber to run the pipe to a drain. So if the plumber wants to save that effort and save those pennies, the plumber can often leave it that the pressure relief valve vents the steam out into the open, and in many localities this will not violate code. But yes, if you are a homeowner and the vent path points toward some expensive furniture, or toward people, then that is not a very happy situation.

For people who want to see what happens when the water heater safety valve is not working and the water heater overheats, you can Google “Mythbusters water heater” and look at the videos you find. Very impressive.

For an example of something in everyday life that one would believe to be linear, but which is not, rubber bands don’t follow the linear relationship between force and elongation. Dustin of Smarter Everyday has a nice video about this https://www.youtube.com/watch?v=1v4TEX2erog.

In opposition to Carl, I was lucky to have professors who explained at least a bit why things seem to be mostly linear. One of the reasons is that in most systems, we are looking at, we are close to equilibirum. Then, if the change in a variable x when we act on the system is f(x), f(x) can be approximated by a Taylor series about equilibrium, and when the changes are small, only the first term f'(x) (x-xe), xe being the value of x at equilibrum, can be observed. The other terms are so small that the deviation from the linear behavior is not observable.

Some people may object that the basic laws of physics are linear, but that is not true! For gravity, general relativity is highly non-linear. Fluid dynamics (one may argue “not a basic law”): also non-linear. Nuclear physics (all of strong force interactions): same.And electromagnetism? Surely Maxwell’s laws are linear and all of electromagnetism is linear? They are, but electromagnetism is also non-linear in complex system. Otherwise, we would not have the whole field of non-linear optics. Almost, if not all, the physics someone who is not majoring in physics will learn is linear, and that gives an illusion that we live in a linear world, but we don’t. However, in complex systems, non-linearities appear. Now, the magic, as Carl calls it, is that in phenomena observed in everyday life, things seem to be linear, and that we can use this linear approximation for a lot of engineering.

Some engineering disciplines need to take into account non-linear phenomena, For example, in chemical engineering. In that case, non-linearities need to be taken into account as soon as pressures, temperatures or concentrations get large enough. However, the complexity is often hidden in the mysterious activity coefficient, which is added as a linearly multiplicative term and somewhat hides the fact that we are dealing with non-linear phenomena.

Here in my neighborhood the spillways and valves are “backward” from what Carl described.

For the lake near me, the spillway was designed for “normal” conditions (i.e., the stream North of me flowing at the “expected” gal/hr and “normal” amounts of rain), and gate valves at the base of the dam were designed to be large enough to deal with “100 year storms”. They were not designed to deal with a “1,000 year storm”, i.e., if things go very badly.

The spillway is large enough that during normal operation, when x gal/hr of water enters the lake at its North end, x gal/hr of water exits the lake through the spillway at the South end of the lake where it flows to the bottom of the dam without touching the dirt on the “dry” side. It passes through the concrete lined spillway.

For our dam, the dam is essentially a cement “membrane” supported on the “dry” side by a large pile of dirt.

The spillway protects the “dry” side of the dam from the erosion that would occur if the water in the lake simply continued to rise until it was high enough to flow over the dam at any old place along the length of the dam.

Thus, in normal operation, the spillway at our lake looks a lot like the one in the picture that Carl provided. On a clear and sunny day, water flows happily through the concrete lined spillway at a rate that is well below the carrying capacity of the spillway. At these times, the dirt holding up the dam does not wash away.

During “normal” rain storms, water flows faster through the spillway, but the capacity of the spillway is still sufficient to safely carry away the extra water.

However, if rain falls fast enough, then the spillway is no longer large enough and the water level in the lake rises. If the top of the water gets to the top of the dam, water will flow over the top of the dam at many points along its length, which would cause serious erosion on the “dry” side. If enough dirt should be washed away, the dam would fail and people living in the valley below would be in a bad place.

Until a few years ago, the operating plan for “our” lake community dam “said” that if there were a very large storm, where the flow of water into the lake was, or was predicted to become, too large for the spillway, some intrepid soul would walk along the top of the dam (where there is no paved way and no hand rails) to the large horizontal wheels which the volunteer operator would then turn to open the gate valves installed at the bottom of the dam, permitting water to “escape” from the lake to the bottom of the “dry” side of the dam by passing through large pipes normally blocked by the gate valves, without eroding the dam.

So, in the old system, the gate valves were designed to be the safety valves — during infrequent but expected storm events. On average, one might expect to see a “100 year storm” about once per 100 years, and the spillway and the gate valves are designed to deal with that (assuming timely operator action).

However, on average, one might expect to see a “1,000 year storm” about once per 1,000 years. The spillway and the gate valves were not designed to handle “1,000 year storms”. The “fail safe” for the “1,000 year storm” is the valley below the dam — if water enters the lake too fast, then before it reaches my home (located above the elevation of top of the dam), water will flow over the dam, the dam will fail and water will flow through the occupied valley below.

——

As a footnote for the interested reader, the gate valves at our dam eventually stuck in the closed position, which increased the risk of dam failure during large storms.

What to do?

Clever people decided to install some large “siphon tubes” that have one end near bottom of the dam on the “wet” side, pass over the top of the dam (I don’t know, but perhaps below the bottom of the spillway so that the tubes can be primed by simply opening a valve), and then terminate near the bottom of the dam on the “dry” side. The new plan is that if there is too much water for the spillway, our intrepid volunteer will start the siphons rather than open the old gate valves.

Since I hope to live for a few thousand years, I am glad that I live in a house that is a few feet above the top of the dam, rather in a house that is in the valley downstream from the dam.