(followup: I have now measured more welding currents — blog article)

It will be recalled (blog article) that I recently took a stick-welding course. I also recently purchased an inexpensive inverter-type welding machine (shown at right), and a neighbor of mine also purchased an inexpensive inverter-type welding machine.

Each welding machine has a rotary knob for picking the welding current. And each welding machine has a three-digit numerical display. The question that arose for my neighbor and me was, can we safely assume that the number in the display will be the number of amperes of actual welding current? The answer turned out to be “no”.

The alert reader will recall that in a previous blog article, I mentioned that I recently acquired a clamp-on DC ammeter, shown at right. It uses some Hall-effect sensors distributed around the loop defined by the orange plastic clamp. What I did was clamp this ammeter around one of the workpiece cables of the welding machine. I then connected my smart phone to the ammeter via Bluetooth to gather and log the current readings. I then used each of two welding machines — my neighbor’s recently acquired inverter welding machine, and my recently acquired inverter welding machine.

I set each machine with a number in the display (using the rotary knob) and did some welding. I logged the current readings using the smart phone. Here you can see some results for the two welding machines:

Yes what we find is that on the S7 welding machine, a dial set to 94 yields a welding current of 60 amps and a dial set to 123 yields a welding current of 72 amps. On the Simder welding machine, a dial set to 94 yields a welding current of 77 amps and a dial set to 123 yields a welding current of 90 amps.

On the S7 welding machine, a dial set to 141 fairly quickly popped a 20-amp circuit breaker. (Recall that this welding machine works only on 120 volts.)

We can assume that the maker of the welding machine intended that the number on the display would be the welding current. With this in mind, the natural question is whether the DC ammeter is wrong or whethr the number on the display is wrong. As a starting guess I would imagine that the numbers on the display are wrong (for both welding machines) given that neither welding machine was able to match the reading on the ammeter. I then checked the ammeter by connecting a bench DC power supply (above right) to a 100-watt 75Ω dummy load (below right) to create a known current.

I then clamped the DC ammeter onto one of the leads to see what it read for the current, comparing this with the current measured by the bench DC power supply. They matched across a range of values.

Based on the fact that the clamp-on ammeter matched the bench DC power supply, and based on the fact that neither of the welding machines displayed a number that matched the current as measured by the clamp-on ammeter, I decided that the most likely explanation is that (a) the clamp-on ammeter is measuring the DC current accurately, and (b) neither welding machine is displaying a number that is the same as the welding current.

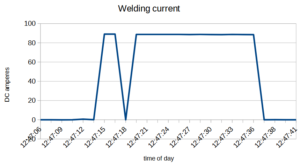

We then turn to an interesting next question, namely how consistent the value of the magnitude of the welding current is during a given welding operation. Does the current go up or down depending on things like the arc length or the way that the user is holding the welding rod? And here is where I really like the Bluetooth smart phone logging capability of this clamp-on DC ammeter. I was able to log the actual welding current during an actual welding session. I configured the smart phone app to log a data point once per second. As you can see from the graph, the welding current was a rock-steady 82 amps. I established an arc for about two seconds, lost the arc briefly, and then re-established the arc, maintaining it for about seven seconds, and at each moment while the arc was established, the current was exactly 82 amps.

These welding machines work well with a 3⁄32” welding rod such as a 7014 rod, with the rod connected to the + terminal of the welding machine and the workpiece connected to the – terminal of the welding machine. When the rod is a 1⁄8” welding rod, I find that with these welding machines, I cannot reliably strike and maintain the arc.

Part of what I find striking about this (so to speak) is that a mere $70 can get you a welding machine that can do decent stick welding with a 3⁄32” welding rod. The welding machine does not take up very much space and is not very heavy.

Can you accurately anticipate what amperage to expect given the readout on the machines as a ratio to the readings you have gotten on the ammeter? Perhaps this is an opportunity to do some more experimentation…

Yes this is a very good question. What I will need to do is a series of test welds with the current-selection knob in various positions. I will then be able to plot “number on the display” on the X axis and “how many amps of welding current you actually get” on the Y axis.

How do you have enough time for all your activities?